- info@carbocraft.co.za

- 011 234 0675

- MONDAY-THURSDAY 8:30-4:30 FRIDAYS 8:30-3:30

Tower Packing & Catalyst Support Media

CARBOCRAFT is thrilled and honoured to work with a leading international producer of a complete range of tower packing and catalyst support media, namely Christy Catalytics, based in the US! Christy Catalytics specialises in ceramic and alumina balls for fixed beds of catalyst and adsorbents, as well as Christy-Pak tower packing and “internals”, in a wide range of configurations and construction materials including ceramic, metal, thermoplastics and carbon/graphite. Due to an excellent and distinguished track record for high-quality products and services, the Christy Catalytics customer and technical approval list includes most of the world's prominent petroleum refiners, chemical producers, EPCs, process licensors, and catalyst/adsorbent manufacturers.

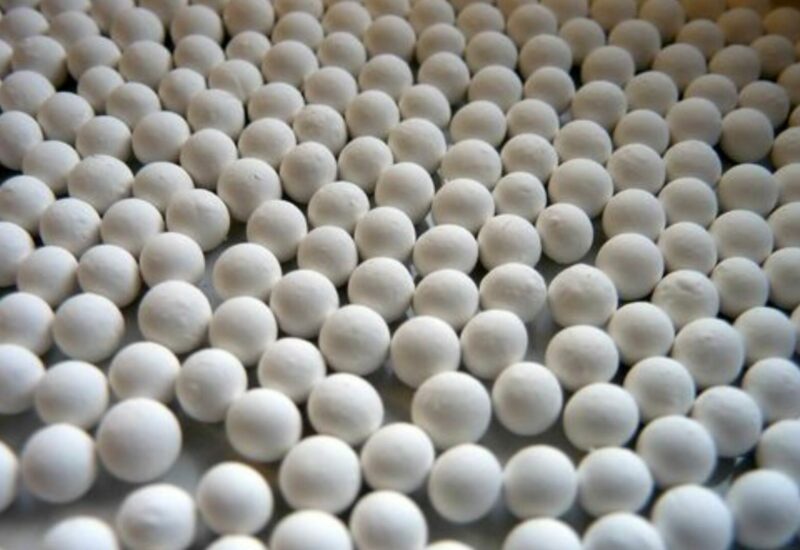

CHRISTY CATALYTICS BED SUPPORT MEDIA – SINCE 1952

Christy Catalytics pioneered the development of spherical inert catalyst bed support media with the introduction of PROX-SVERS® T-22 in 1952. Today, the PROX-SVERS® line offers the widest variety of alumina and silica-alumina ceramic formulas for use in nearly every type of fixed bed reactor in the petroleum refining, petrochemical, and gas processing industries. Consequently, Christy has become one of the world’s largest suppliers of engineered inert catalyst bed support media.

With nearly 100 years of experience in ceramics and refractory materials, Christy manufactures and supplies a comprehensive range of reactor internals and peripherals. This includes essentials for the synthesis gas industries such as alumina hex tiles, reformer tunnel wall bricks and cover slabs, dense and insulating firebrick, burner blocks, and ceramic fiber. Christy also offers a variety of high-quality, cost-competitive tower packing and internals, including ceramic saddles, Pall Rings, Raschig rings, and advanced IMTP-comparable metal packings, to meet your most demanding needs.

- T-38 PROX-SVERS®are Christy’s premium grade inert ceramic support media. They contain a higher alumina content than any other ceramic support balls on the market, allowing them to be used in applications with operating temperatures up to 1370°C. The unique T-38 microstructure provides excellent thermal and pressure shock resistance. In fact, the proprietary formula of T-38 results in the highest physical properties of any ceramic support ball world-wide. Use T-38 in your most demanding applications where other ceramic balls don’t work.

- T-86 PROX-SVERS®ceramic support balls are Christy’s industrial grade inert ceramic support media. They are used as catalyst support in a variety of applications in refineries, synthesis gas and other petrochemical processes, with installations around the world. Common applications include adsorbent or desiccant beds, desulfurization, or hydro-processing.

- T-99 PROX-SVERS®alumina balls, composed of high purity, sintered alpha-alumina with very low silica levels, are an excellent choice for steam reforming in synthesis gas production or other high temperature applications where the presence of high-water partial pressures can cause silica leaching. T-99 alumina balls are an excellent choice for supporting adsorbents used in purifying reactive monomers like ethylene, propylene, and styrene due to their low levels of other impurities such as iron, titania, and alkalis. The ultra-low porosity, very high density and outstanding thermal shock resistance of T-99 alumina balls make them ideal for regenerative burner and filtering media for the metals industry.

- T-46 PROX-SVERS®alumina balls are formulated specifically for the synthesis gas industries to prevent silica leaching in the presence of high-water partial pressures. T-46 has an excellent 50-year track record of service in the ammonia industry.

- Christy’s CATA-COGS™ are specialty hold-down and support media which can dramatically reduce pressure drop in reactors such as Water Shift Converters due to their significantly increased void fraction when compared to ceramic or alumina balls. CATA-COGS™ are available in both our 99% alumina and ceramic formulations.

Hexagonal Target Tiles

Christy’s CUSTOM-CRAFTEDTM Hexagonal Target Tiles are now used in over 50 ammonia plant secondary reformers. While being specified by KBR in their process, the tiles are also used in any design such as Haldor Topsoe or Uhde reactors with a central riser. Made of low silica alumina refractory mix, the hexagonal target tiles lock into each other to provide very high lateral stability in the face of turbulent gas velocities. The extremely durable 99% alumina formula also provides superb erosion resistance.

A ring of Christy’s unique circle brick around the perimeter prevents gas bypass around the outside edges of the hexagonal target tiles Most recently, Christy is pleased to introduce HT-LC Low Corrosion Material available as both Hexagonal Target Tiles and PROX-SVERS® Support Ball. HT-LC has been developed to resolve high temperature corrosion in Secondary Reformers and ATRs. HT-LC Hex-Tilesand PROX-SVERS are manufactured using a proprietary, low corrosion metal oxide formulation which resolves the corrosion of Al2O3, SiO2, K2O and Na2O contained in 99% alumina materials from exposure to the high temperature process gas. Once corroded, these materials deposit downstream either in the catalyst bed or in the waste heat boiler leading to reduced efficiency and shut down. HT-LC is the solution to this problem.

In addition to enhanced corrosion resistance, Christy’s HT-LC formulation provides superior catalyst hold-down due to their 60% higher density compared to 99% Al2O3 materials. Alternatively, the height of HT-LC hex-tiles can be reduced to maintain an equivalent Hex-Tile weight and reduce cost. HT-LC Hex-Tiles are available in the same sizes and configurations as HT-95 and HT-99 including Standard, Jumbo and Super Jumbo Hex-Tiles as well as Circle Brick for installation around the perimeter of the vessel. HT-LC PROX-SVERS are available as 38mm, 50mm, and 76mm diameter balls.

Tower packing and “internals” play a vital role in various chemical and industrial processes, particularly in distillation, absorption, stripping, and scrubbing operations. They are designed to optimize mass transfer and increase the surface area for efficient contact between the gas and liquid phases.

Tower packing refers to structured or random arrangements of individual elements or materials placed within a tower or column. Its purpose is to provide a large interfacial surface area for intimate contact between the gas and liquid phases, allowing for efficient mass transfer. This enhances the separation and purification processes.

- Random Packing: Random packing consists of randomly shaped objects or bulk materials such as ceramic, metal, or plastic pieces. These objects are filled within the column and provide a large surface area for increased contact between the gas and liquid phases. Popular types of random packing include Raschig rings, Pall rings, Intalox saddles, and Berl saddles.

- Structured Packing: Structured packing consists of specially designed elements with specific geometry, surface area, and flow characteristics. These elements are arranged in a particular pattern to optimize mass transfer efficiency. Structured packings typically have a regular shape or repeated geometrical patterns, such as corrugated sheets, gauze grids, or wire mesh. They offer higher efficiency compared to random packings due to their well-defined surface area and uniform distribution of liquid and gas flow.

Tower “internals” are additional components within the column that help enhance the overall performance and efficiency of separation processes.

- Distributors are positioned at the top of the column and are responsible for evenly distributing the feed or liquid phase across the cross-section of the tower. They ensure a uniform flow of liquid over the packing to maximize the mass transfer efficiency.

- Liquid collectors, located at the bottom of the column, collect the processed liquid, and direct it to the next stage of the process or to the product storage. They prevent any liquid bypassing or channelling.

- Vapour collectors are placed at the top of the column to collect the processed vapor or gas and direct it either to the overhead condenser or to downstream processes. They prevent any liquid droplets from being carried over in the gas phase.

- Support plates or grids are positioned at various elevations within the column to provide structural support to the packing material. They maintain the integrity of the packing and allow for efficient flow distribution.

- Liquid redistributors are used in cases where liquid maldistribution occurs. They ensure a more even distribution of liquid across the column cross-section, ensuring optimal performance of the packing material.

- Mist eliminators are devices used to separate entrained liquid droplets from the gas or vapor phase. They prevent liquid carryover in gas streams, ensuring high product purity and protecting downstream equipment.

Christy® Pak Metal Pall Rings

Christy® Pak Metal Pall Rings are available in a variety of sizes and metallurgies, including carbon steel, stainless steel, Inconel, brass, copper, and nickel alloys. The windows in the cylinder walls provide higher density and lower pressure drop compared to standard cylindrical rings.

Christy® Pak Metal Raschig Rings

Christy® Pak Metal Raschig Rings are a first generation of tower packing. They have good surface area and can handle heavy loading. Christy® Pak Metal Raschig Rings are offered in a variety of sizes and alloys.

Christy® Pak Ceramic Saddles

Christy® Pak Ceramic Saddles is one of the most popular form of tower packing, offering high resistance to chemical attack and thermal shock. Christy® Pak Ceramic Saddles are commonly used in heat transfer applications and in corrosive atmospheres. Christy® Pak Ceramic Super Saddles offer improved mass transfer efficiency and lower pressure drop.

Christy® Pak Ceramic Raschig Rings

Christy® Pak Ceramic Raschig Rings are fired at high temperatures and have excellent mechanical strength, abrasion, and acid-resistance. They can resist corrosion from various organic solvents and can be used in high or low temperature applications e.g. drying columns, absorbing columns and cooling towers.

Christy® Pak Carbon Raschig Rings

Christy® Pak Carbon Raschig Rings These rings are extensively utilized in the hydrocarbon industry and are well-suited for harsh environments involving acids, caustics, and solvents. They exhibit excellent corrosion resistance and can withstand high temperatures. Carbon Raschig Rings are characterized by a low coefficient of thermal expansion, which protects them from damage due to severe shocks.

Christy® Pak Plastic Pall Rings

Christy® Pak Plastic Pall Rings are applied in lower temperature applications. Christy® Pak Plastic Pall Rings are made from thermoplastics e.g. PE, PP, RPP, PVC, CPVC and PVDF, and offer properties such as high void ratio, low pressure drop, low specific weight and high mass transfer efficiency. Applications: alkali industry, coal gas, environmental protection industry.

Christy® Pak Arch Saddles

Christy® Pak Arch Saddles are the second generation of metal tower packing. Christy® Pak Arch Saddles are an alternative to Intalox® Metal Tower Packing saddle.

Christy® Fill Heat Transfer Media

Christy® FILL Honeycomb provides outstanding heat transfer characteristics. Its thin walls facilitate effective heat exchange, while the laminar gas flow through channels prevents blockage, particle adsorption, and chemical attack. Available in cordierite, dense cordierite, alumina, and mullite, Christy® FILL Honeycomb offers a range of geometries including square, triangle, and hexagonal shapes.

Christy® Synthesis Gas and Ethanol Solutions

The feedstock, production processes, and uses of synthesis gas present some of the most intriguing aspects of today’s chemical industry. New feedstocks, including coal and pet coke, are emerging. Novel catalyst technology and process improvements are often seen.

Emerging end uses e.g. GTL and CTL motor fuels, are expanding the uses of synthesis gas beyond the well-known and traditional applications of ammonia, methanol, and hydrogen. Christy offers solutions for almost every step of synthesis gas production, regardless of end-use.

There are many reasons why over 100 vacuum-swing ethanol driers use Christy PROX-SVERS® Ceramic Bed Support Balls for their MOLE SIEVE BALLAST. The most obvious is that the rapid pressure swing cycles can abuse the mole sieve media and even fluidize the entire bed causing attrition and loss of proof. Christy T-38 and T-86 PROX-SVERS® MOLE SIEVE BALLAST is durable, and its weight locks the mole sieve into place, so it can do its job and last for years. For extreme conditions where beds have been “flipped”, consider our efficient, resilient high-density T-99 PROX-SVERS® ALUMINA BALLS or alternatively our tailor-made CUSTOM CRAFTED™ HEXAGONAL TARGET TILES for added stability.