- info@carbocraft.co.za

- 011 234 0675

- MONDAY-THURSDAY 8:30-4:30 FRIDAYS 8:30-3:30

Carbon Molecular Sieves (CMS)

CARBOCRAFT supplies a full range of Carbon Molecular Sieves to cover all the known commercial applications of today! The versatility, selectivity, and tunability of our CMS materials make them almost indispensable in various industries, particularly where separation and purification of gases are required.

Highly Efficient Adsorbents

Carbon molecular sieves are highly efficient adsorbents produced from carbonaceous materials, such as coal, coconut shells, or wood, that have been treated with various chemicals to create a highly porous structure with a large surface area. CMS works by selectively adsorbing certain gases and molecules based on their size and shape. The porous structure of CMS consists of a network of interconnected channels and pores that trap smaller molecules while allowing larger molecules to pass through. This allows for the separation and purification of gases, such as nitrogen and oxygen, from air and other gas mixtures.

In addition to its use as an adsorbent, CMS also has applications in energy storage and water purification. Its high surface area and porosity make it an ideal material for use in supercapacitors, batteries, and fuel cells. CMS can also be used to remove impurities from water by selectively adsorbing certain contaminants while allowing clean water to pass through the pores.

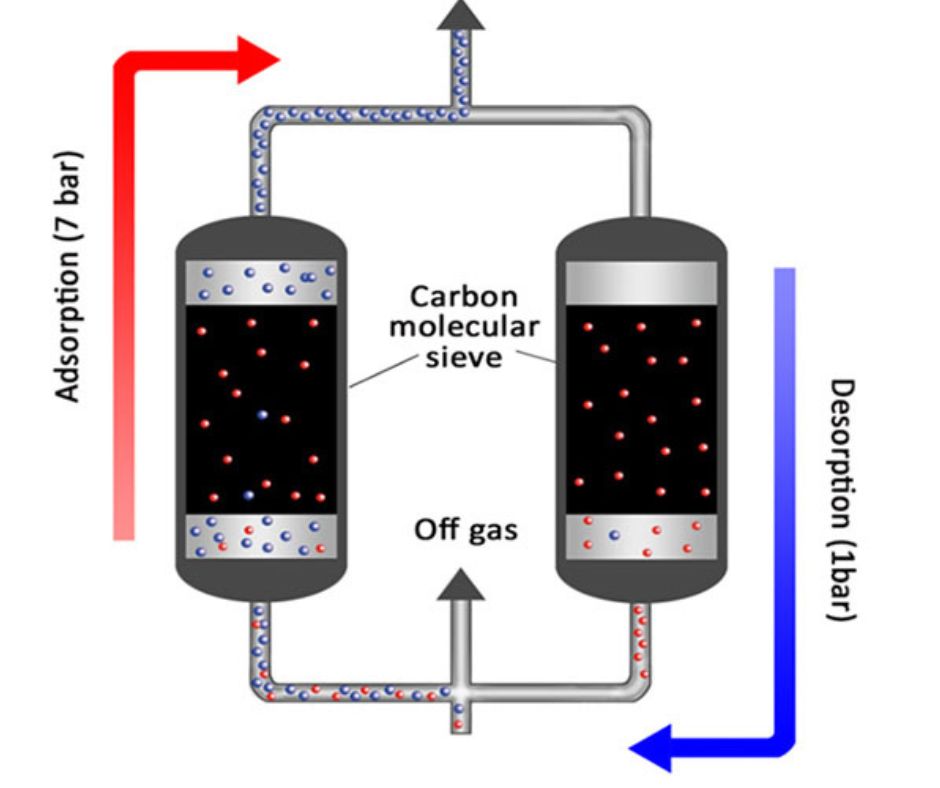

CMS (Carbon molecular sieves) and PSA (Pressure Swing Adsorption) process are two closely related terms that are used in gas separation applications. The PSA process is a gas separation technique that uses a bed of adsorbent material, such as CMS, to selectively remove one or more gases from a mixture of gases at high pressures. The adsorbent selectively adsorbs one or more gases in the mixture, while the other gases pass through the bed. The adsorbed gases are then released from the adsorbent by reducing the pressure, which causes the gases to desorb and be collected for further processing.

CMS is an ideal adsorbent material for the PSA process due to its high surface area, porosity, and ability to selectively adsorb certain gases. CMS can be tailored to adsorb specific gas molecules based on their size, shape, and polarity. This allows for the efficient separation of gases from mixtures, including air separation into oxygen and nitrogen.

In the PSA process, the pressure within the adsorption bed is periodically cycled between high pressure and low pressure to allow for adsorption and desorption of the gas mixture. The cycle time and other process parameters depend on the specific application and the characteristics of the gas mixture.

CARBOCRAFT has the right type of CMS adsorbent for your specific type of application, which may include (but is not limited to) the following:

- Gas separation: CMS is extensively used in gas separation processes, particularly in the production of nitrogen and oxygen from air. It is employed in Pressure Swing Adsorption (PSA) systems to selectively adsorb and separate gases based on their molecular size and properties.

- Bioethanol purification: CMS can be used in the purification of bioethanol by selectively adsorbing impurities and by-products such as water, acetic acid, and other volatile organic compounds.

- Hydrogen purification: CMS can effectively remove impurities and purify hydrogen gas streams. It helps in achieving high purity hydrogen required in various applications such as fuel cells, electronics, and other industrial processes.

- Natural gas processing: CMS is employed in natural gas processing plants to separate and remove impurities such as carbon dioxide, water vapor, and other trace components from the natural gas stream.

- Carbon dioxide (CO2) capture: CMS captures carbon dioxide from post-combustion gases, which can significantly reduce greenhouse gas emissions.

- Petrochemical refining: CMS is instrumental in the separation and purification of various gases, including the removal of impurities from gas streams, catalytic reactor protection, and olefin/paraffin separation.

- Solvent recovery: CMS can aid in the recovery of solvents used in various industrial processes by selectively adsorbing and separating the solvents from other components.