- info@carbocraft.co.za

- 011 234 0675

- MONDAY-THURSDAY 8:30-4:30 FRIDAYS 8:30-3:30

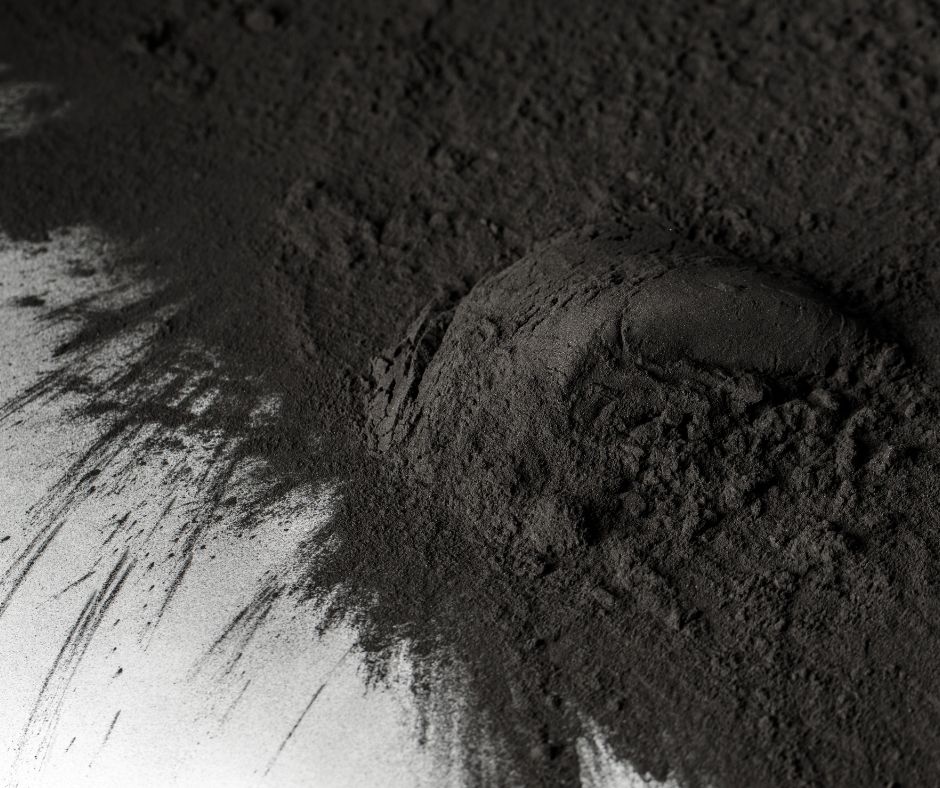

Activated Carbon

CARBOCRAFT was founded on ACTIVATED CARBON, and as such, we still supply a full range of superior activated carbon products crafted from bituminous coal, wood and coconut shells.

Adsorb • Chemisorb • Decaffeinate • Dechlorinate • Decolorize • Decontaminate • Deionize • Deodorize • Desorb • Detoxify • Purify

Powdered Activated Carbon (PAC) + Granular Activated Carbon (GAC) + Extruded Activated Carbon (EAC)

Our products are available in powder, granular and extruded pellet form, to cover the complete spectrum of adsorption applications. Our products have been specially designed with an extremely high surface area and an optimum level and ratio of macropores vs. micropores, to facilitate excellent adsorption characteristics in every known feedstock.

Our activated carbon grades are also manufactured with suitably “application-matched” particle sizes, with a minimum percentage of “fines”, ensuring a good general filterability with optimum filtration flow rates and cycle times, enabling our customers to maximize their plant productivity. Our products are produced in accordance with the highest quality standards and all relevant quality certificates are available upon request e.g. NSF, ISO, IFS, food-safety, Kosher, Halal, etc.

Activated Carbon is an extremely useful process aid that is used to deodorize, decolorize and purify a myriad of different feedstocks. Due to its high degree of microporosity, one gram of activated carbon has a surface area of more than 3,000m2 (as determined by gas adsorption). The carbon surface is non-polar which results in an affinity for non-polar adsorbates such as organic compounds.

Adsorption is a surface phenomenon in which an adsorbate is held onto the surface of the carbon particle by Van der Waals forces and adsorption saturation is represented by an equilibrium point. These forces are physical in nature, which means that the process is reversible (using heat, pressure, etc.).

These properties make activated carbon a unique and highly versatile process aid and the applications are consequently extremely widespread and encompass:

- air and gas purification

- air filters in respirators

- capacitive deionization

- decaffeination

- edible electronics

- filters in compressed air

- food and beverage processing

- gold purification

- medicine production

- metal extraction

- methane & hydrogen storage

- production of hydrogen chloride

- sewage treatment

- solvent recovery

- super capacitive swing adsorption

- teeth whitening

- water purification

- …and many other applications.