- info@carbocraft.co.za

- 011 234 0675

- MONDAY-THURSDAY 8:30-4:30 FRIDAYS 8:30-3:30

Filter Sheets

CARBOCRAFT is extremely proud and honoured to be the official distributor for a leading international producer and supplier of premium filter media!

CARBOCRAFT specializes in complete depth filtration solutions, with our business revolving around the distribution of premium quality depth filtration media for the full spectrum of filtration applications, including food and beverage processing, spirits, wine, fine and speciality chemicals, cosmetics, pharmaceuticals, and biotechnology. Our products encompass every fathomable filter sheet and filter paper used commercially today: washable support filter sheets, depth filter sheets, clarification, sterilization, activated carbon depth filter media, industrial oil filter paper, plant oil filter paper, etc.

CARBOCRAFT places great importance and ample emphasis on consistently delivering products of the highest quality, and a rigorous and stringent Quality Management System (in accordance with ISO:9001) has been implemented to guarantee 100% product and quality compliance with domestic and international quality standards.

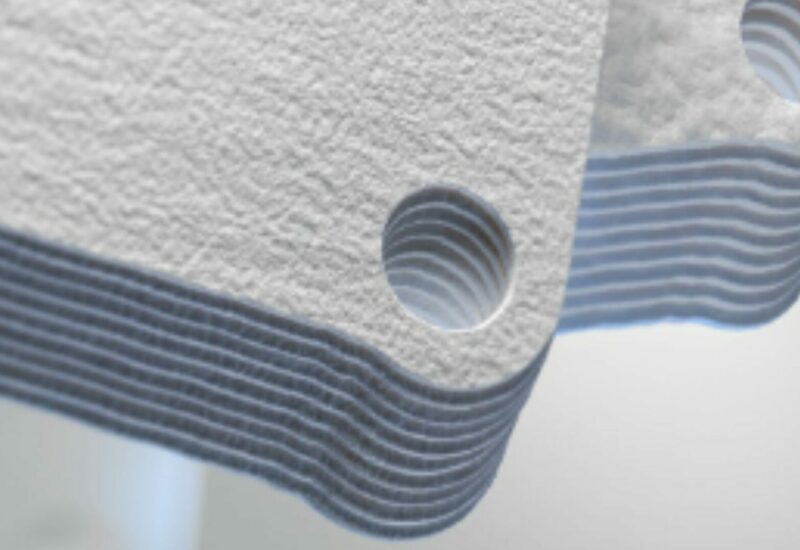

Depth filtration is a multi-layered filtration process that involves passing a liquid through a porous medium to capture suspended particles and impurities. The filtration media used in depth filtration is crucial in achieving efficient and effective separation. The media is designed with different properties to cater to specific applications, providing diverse capabilities for particle retention and liquid flow.

- Composition: Depth filtration media is composed of various materials, such as cellulose fibres, diatomaceous earth, perlite, activated carbon, and polymeric materials. The combination of these materials in different layers forms a depth filter matrix.

- Porosity: One of the fundamental characteristics of depth filtration media is its porosity. The porous structure allows the liquid to pass through the media while trapping contaminants. The porosity of the media is determined by the size and distribution of the pores, which can be tailored based on specific particle size requirements.

- Gradient Density: Depth filtration media typically exhibit a gradient density, meaning the pore size decreases progressively from the inlet to the outlet side. This gradient structure enhances the filtration efficiency by capturing larger particles near the surface while retaining smaller particles deeper within the media.

Pharmaceutical Industry: Depth filtration media is extensively used in the pharmaceutical industry for the clarification of process liquids, removal of particulates, and purification of active pharmaceutical ingredients (APIs). The media’s fine particle retention capability ensures the production of high-quality drugs and avoids contamination.

Food and Beverage Industry: In the food and beverage industry, depth filtration media plays a vital role in removing suspended solids, yeast, bacteria, and other impurities. It is commonly used for the filtration of juices, alcoholic beverages, edible oils, beer, and wine, ensuring product stability, clarity, and taste.

Chemical Industry: Depth filtration media finds applications in the chemical industry for the separation of catalyst particles, purification of solvents, removal of pigments, and clarification of process liquids. It assists in maintaining product quality and extending the operational life of equipment.

Efficiency: Depth filtration media can achieve high particle removal efficiencies, with the ability to capture particles ranging from a few microns to several hundred microns. The gradient density design enhances filtration performance and prolongs filter life.

Capacity: Due to the multi-layered structure, depth filtration media has a large dirt-holding capacity compared to other filtration methods and media. This allows longer filtration operation without frequent filter replacements, reducing downtime and associated costs.

Flexibility: Depth filtration media can be customized based on specific application requirements. The composition, porosity, and gradient density can be tailored to address variations in particle size, liquid flow rates, and filtration performance.

Cost-effectiveness: Compared to other filtration methods such as membrane filtration, depth filtration media offers significant cost advantages. It is generally more affordable, and the longer filter life reduces maintenance expenses considerably.

Depth Filtration Media: Product Overview Synopsis

The following represents merely a SYNOPSIS of our range of depth filtration media. In addition to a diverse portfolio of filter sheets, various types of filter paper are also available, such as activated carbon filter paper for electroplating, wet strength filter paper, high viscosity fluid filter paper, fine particle filter paper, creped filter paper, oil filter paper, frying oil filter paper and many more.

This series filter sheets are specifically designed for blood products. These filter sheets possess exceptional lipid removal capabilities, effectively eliminating lipid residues in blood. With high-quality materials and precise design, they ensure the stability and reliability of filtration, allowing blood products to be handled with ease. Whether used for blood transfusion, plasma preparation, or other blood processing procedures, this series filter sheets are a reliable choice, providing users with efficient and pure blood products.

This series is a new type of washable, reusable support sheet for pre-coat filtration in diatomaceous earth frame filters, for extremely high reliable filtration performance in the food and beverage industry. These filter sheets only serve as precoat support, while the kieselguhr or other filter aid performs the actual filtration and separation. Its high wet strength and optimized surface enable a service life up to 30 precoat cycles, depending on the liquid to be filtered and the filter aid used.

- Robust sheet surface for increased sheet life and heavy-duty use, innovative sheet surface for improved cake release.

- Extremely durable and flexible, perfect powder retention capacity and lowest drip-loss values.

- Available as folded or single sheets to fit any of the filter press sizes and types.

- Very tolerant of pressure transients during the filtration cycle.

- Flexible collocation with various filter aids e.g. kieselguhr, perlite, activated carbon, polyvinylpolypyrrolidone (PVPP).

Beer, food, fine/specialty chemistry, cosmetics.

This Series offers a comprehensive selection of retention grades, effectively spanning particle separation sizes from 0.2 µm to 20 µm. Thanks to its ideal pore structure and excellent adsorption properties, these depth filter sheets deliver outstanding clarification performance across multiple grades. They are well-suited for microbial reduction and are ideal for applications that demand polishing, fine filtration, clarifying, and coarse filtration.

Homogeneous and consistent media available in multiple grades with high wet strength for stability.

Utilizes a combination of surface, depth, and adsorptive filtration with an ideal pore structure ensuring reliable retention of components.

Made from high-quality raw materials to achieve superior clarification performance.

Offers economic service life through high dirt holding capacity and undergoes comprehensive quality control of all materials.

In-process monitoring ensures consistent quality.

Clarifying Filtration and Coarse Filtration: SCP-309, SCP-311, SCP-312 depth filter sheets feature a large-volume cavity structure, offering high particle retention capacity, ideal for clarifying filtration.

Microbe Reduction and Fine Filtration: SCP-321, SCP-332, SCP-333, SCP-334 depth filter sheets ensure high clarity and effectively retain ultrafine particles, suitable for haze-free filtering prior to storage and bottling.

Microbe Reduction and Removal: SCP-335, SCP-336, SCP-337 depth filter sheets with a fine-pored structure and electrokinetic potential achieve high germ retention rates. Ideal for cold-sterile bottling or storage of liquids. These sheet types are particularly suitable as pre-filters for subsequent membrane filtration due to their high retention capacity for colloidal ingredients.

Wine, beer, fruit juices, spirits, food, fine/specialty chemistry, biotechnology, pharmaceutical, cosmetics.

This series products are widely adopted for clarifying filtration, fine filtration, germ-reducing filtration, and germ-removing filtration across various industries. They are commonly used in the filtration of spirits, beers, syrups for soft drinks, gelatins, cosmetics, as well as a wide range of chemical and pharmaceutical intermediates and final products.

This series depth filter sheets are designed with enhanced sediment absorption capacity to meet the demands of larger filtration fluxes. These sheets offer outstanding clarification performance and are widely utilized in specialized and challenging applications.